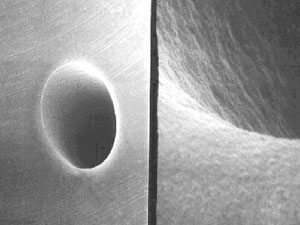

![]() Precision components require precision manufacturing techniques. The Extrude Hone® MICROFLOW abrasive flow process is designed to achieve precise results under tight tolerances.

Precision components require precision manufacturing techniques. The Extrude Hone® MICROFLOW abrasive flow process is designed to achieve precise results under tight tolerances.

Extrude Hone AFM MICROFLOW offers refined control of the abrasive flow process to achieve precise, consistent results for complex applications.

MICROFLOW TEST provides high precision flow measurement technology that refines control of the machining process. MICROFLOW TEST was designed as a result of decades of fuel system processing experience on large-scale automated systems.

MICROFLOW MEDIA is a formulated solution distinguishable by viscosity, particle size, particle type and density. The abrasive particles are mixed into the media solution.

Specific characteristics of our MICROFLOW process include:

- Remote service tracking and standardized components.

- Easy integration into automated production systems.

- Ability to operate in manual or automated modes.

- Media flows in one direction, same as flow through component during operation.

- Real-time monitoring of abrasive media flow through small passages.

- Achieves specific and repeatable processing that results in production stability.

- Versatility – can be utilized as a lab or production machine.

Trust our experts to manage these key process considerations:

- Pressure drop within the component during operation.

- Desired flow rate through the component during operation.

- The geometry of the flow path through the component.

- The properties of the fluid during component operation.

- Workpiece characteristics.

- Media properties.