TEM FOR SUPPORT REMOVAL (IN COLLABORATION WITH EOS) AT TCT DETROIT NEXT WEEK

At Formnext, Extrude Hone announced a new method to remove support structures in inaccessible spots… in a blink! Next week it will be TCT again in Detroit

Among all the announcements made last year, one gained great attention within the AM business community: Extrude Hone and EOS unveiled a thrilling collaboration aimed at addressing chemical-free, simultaneous and ultra-fast removal of Metal DMLS support structures.

The main reason behind AM’s rapid growth is, in a word, competitiveness. Companies adopting AM gain a competitive advantage, which in many cases belong to new processes and products, enhanced by the freedom of design enabled by this technology. However, in many cases engineers’ creativity is still constrained by post-processing issues. One example speaks for all: support removal in inaccessible, or hard to reach, areas.

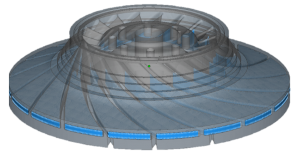

The impeller depicted in Figure 1 for example would be a perfect fit for additive manufacturing but, until today,  support structure removal in the twisted (inaccessible) channels made it an impossible build. Thanks to research and testing carried out jointly by Extrude Hone and EOS however, this isn’t the case anymore!

support structure removal in the twisted (inaccessible) channels made it an impossible build. Thanks to research and testing carried out jointly by Extrude Hone and EOS however, this isn’t the case anymore!

Combining specially designed Support Structures by EOS’ engineers, with an Advanced T.E.M. (Thermal Energy Method) process developed by Extude Hone, we were able to achieve impressive results. The part was post-processed with T.E.M. in a few milliseconds – for a total cycle-time below 10sec – and all support structures, in every single channel, were removed successfully.

A short (40min) cycle of Abrasive Flow Machining took the final roughness value down to an amazing 1.6µm Ra. This is not only interesting per se but becomes even more important if you think this part could not be produced at all, with current technology offerings. Together with our partner, EOS we are pushing forward the boundaries of AM.

The TEM process, well-known in the industry for deburring, basically consists of a controlled ignition, which takes place in a contained and well controlled environment (Extrude Hone’s TEM Equipment, labeled “T Series”). The way Extrude Hone controls how the ignition takes place, combined with the special geometry of the support structures generated by EOS’ software, literally blows away all supports – and this happens so fast (in the order of milliseconds) that it doesn’t harm the part nor change its mechanical properties in any way.

Extrude Hone is already well recognized as an industry leader for surface improvement and surface enhancement technologies in the AM industry, and is currently expanding its overall AM capabilities as well, including in house 3D Printing and now, complete support structures removal as well!

Extrude Hone Additive, our dedicated Business Unit for AM, offers top-notch solutions spanning from design to finishing – positioning itself as high-end one-stop-shop for the aerospace, medical, automotive and energy industries among others.

To discover more contact us or come visiting us during next week’s TCT Detroit – Booth 1159